- Strings

-

Ultramag Bass

Type 52 Alloy Roundwound -

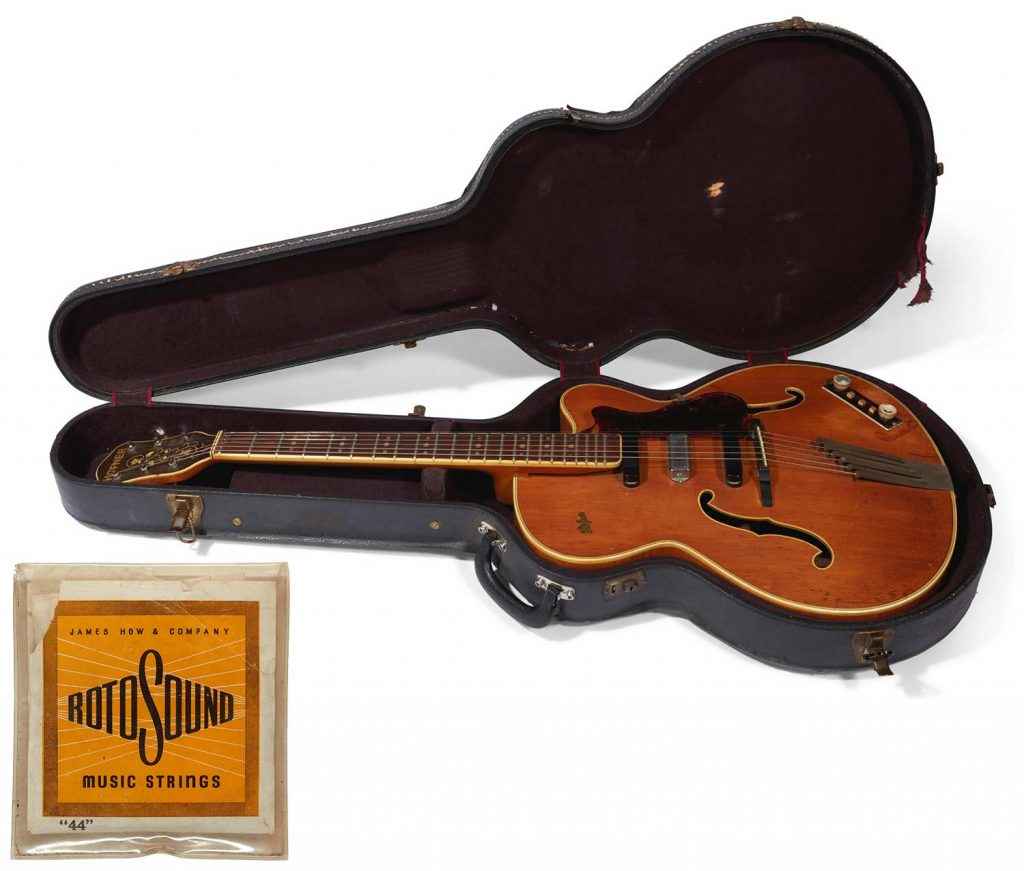

Bronze Bass 44

Phosphor Bronze Acoustic -

Solo Bass 55

Stainless Steel Pressurewound -

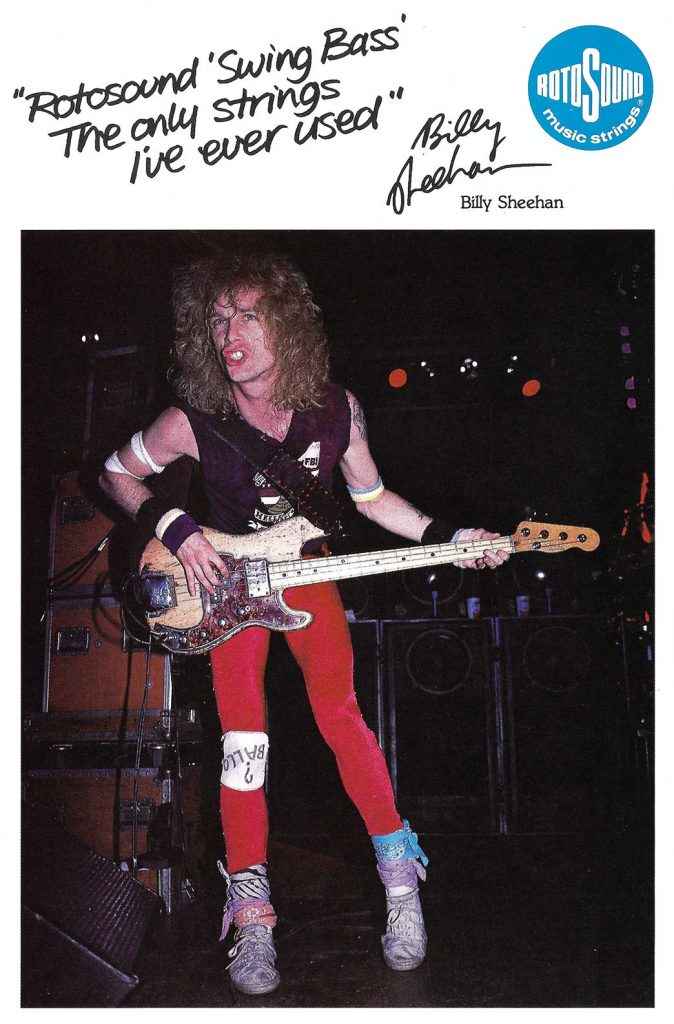

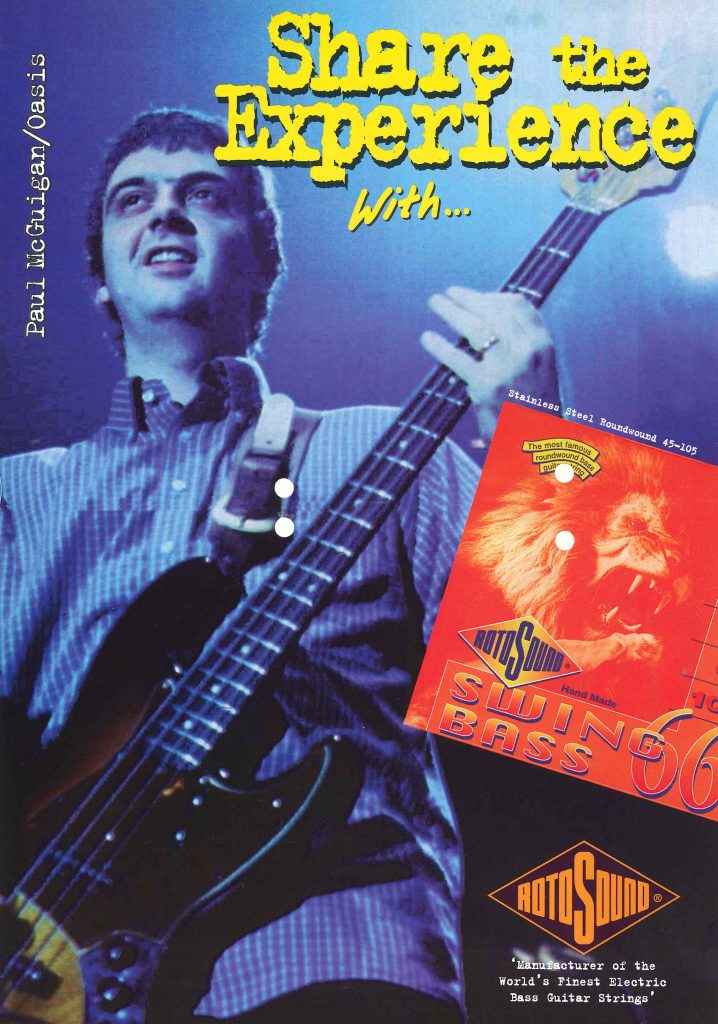

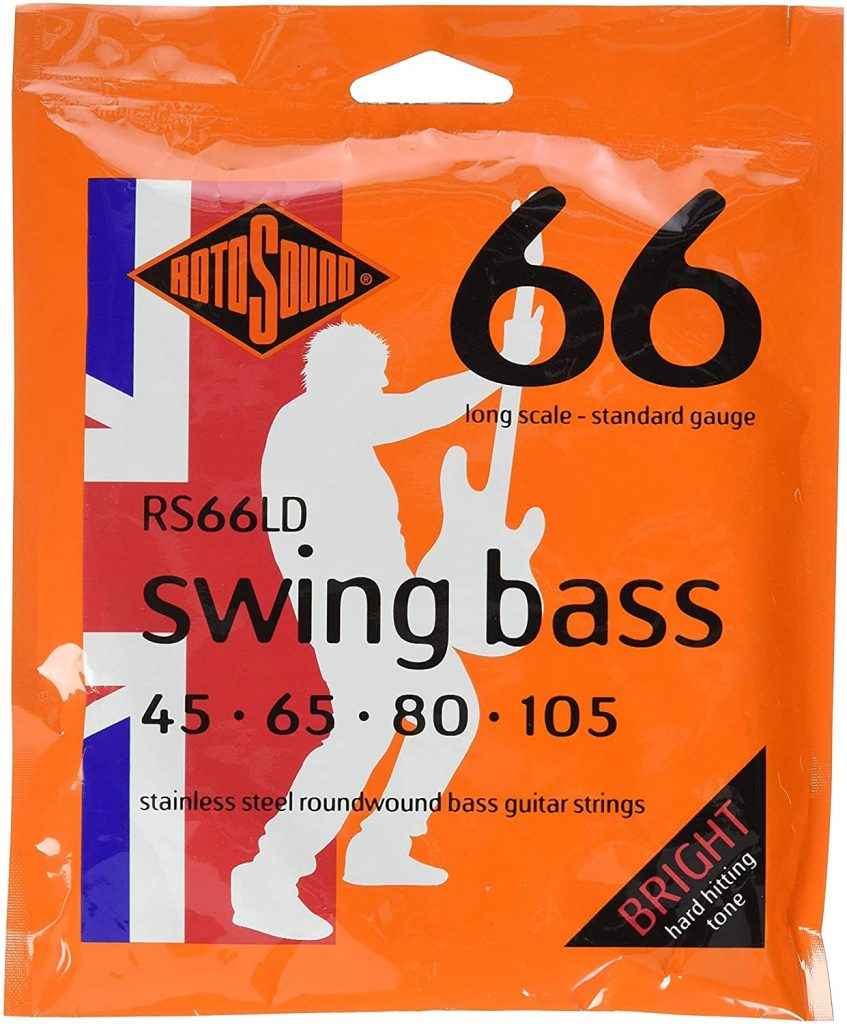

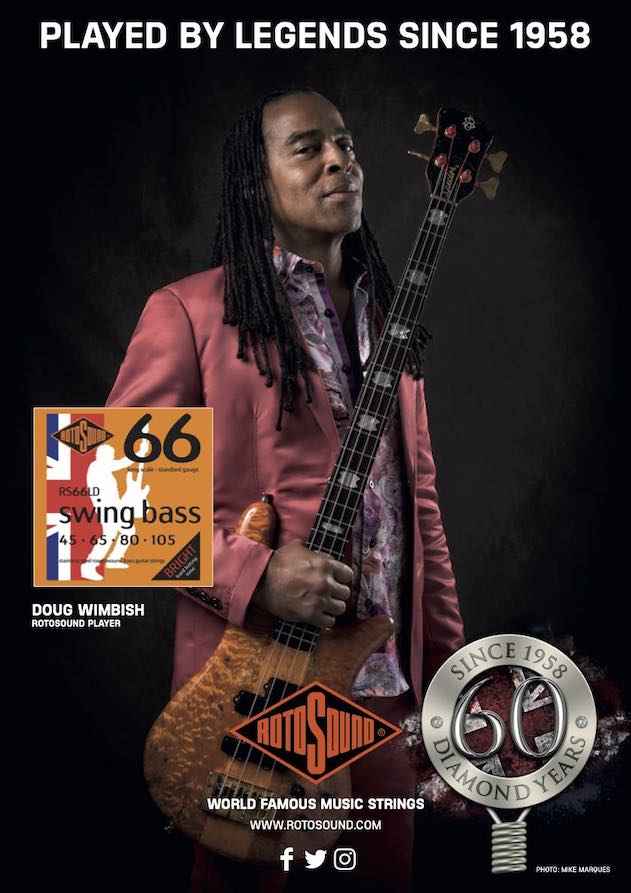

Swing Bass 66

Stainless Steel Roundwound -

Dropzone 66

Designed For Drop Tuning -

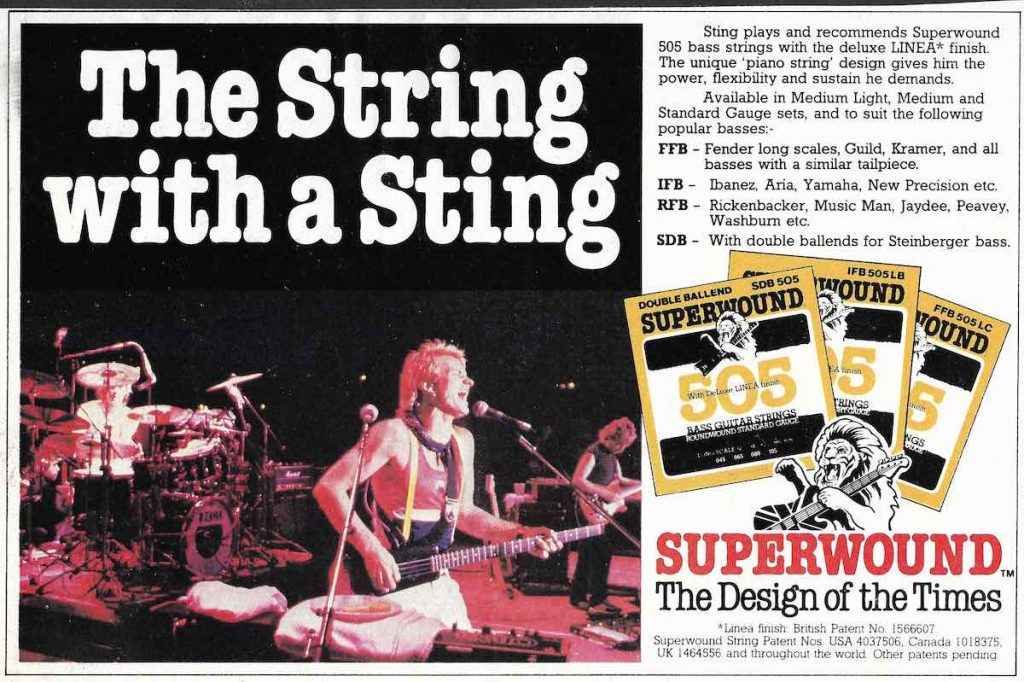

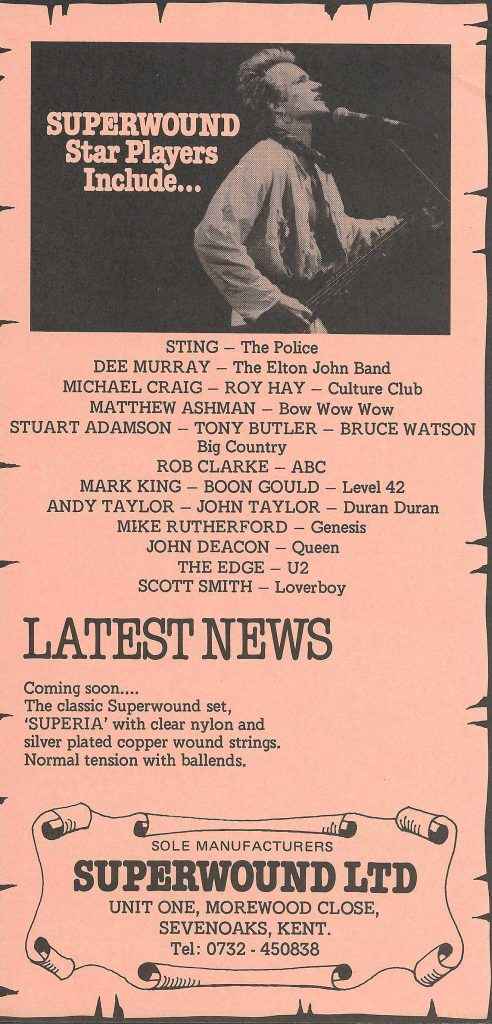

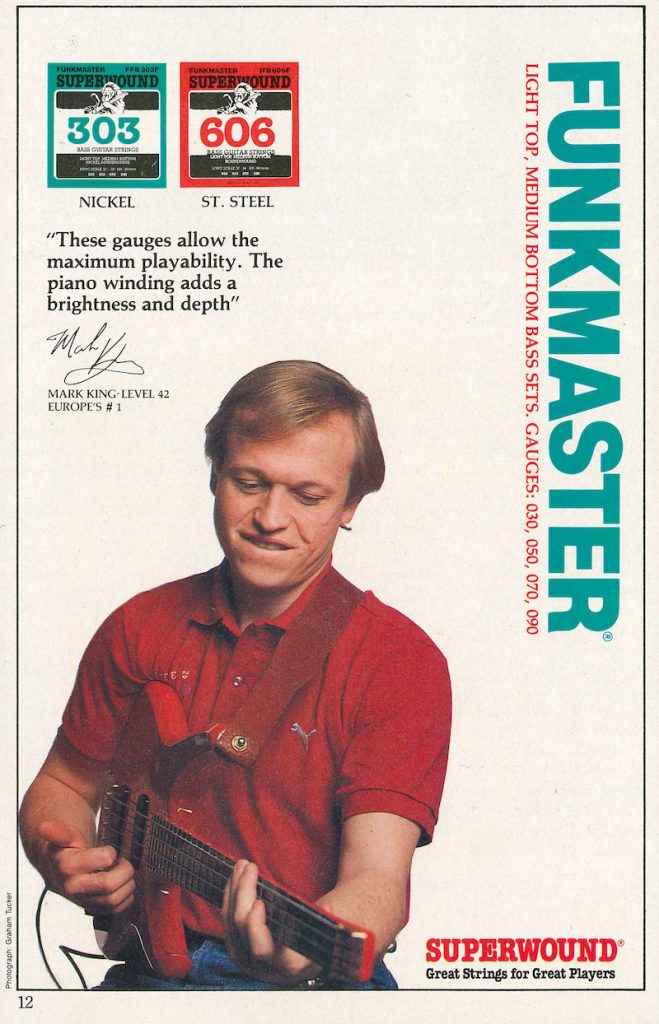

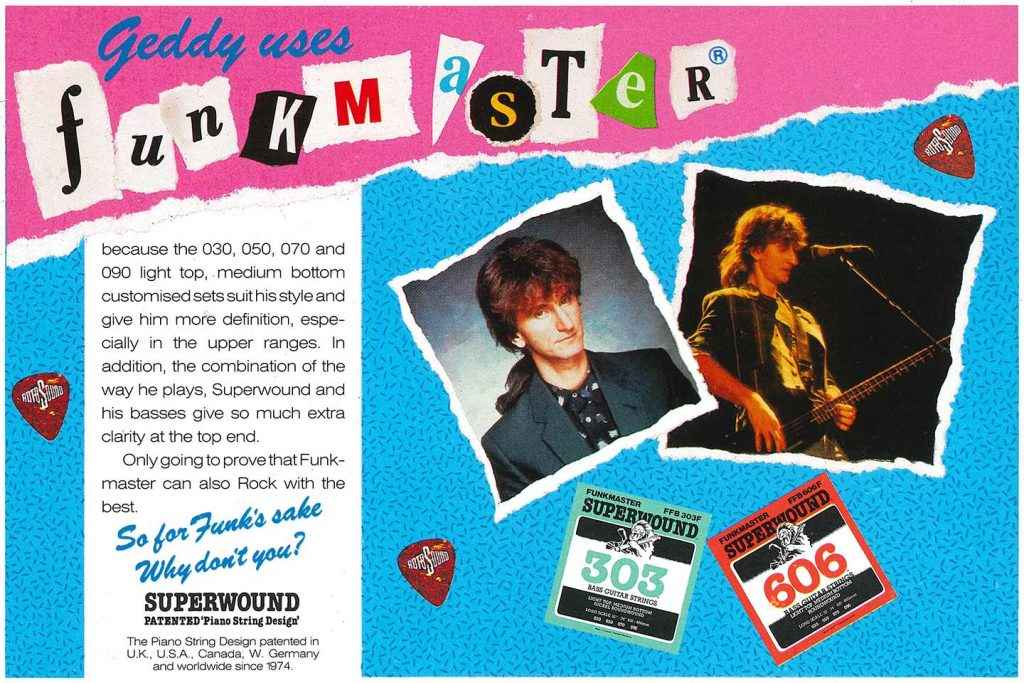

Funkmaster 66

Made For Slap Bass -

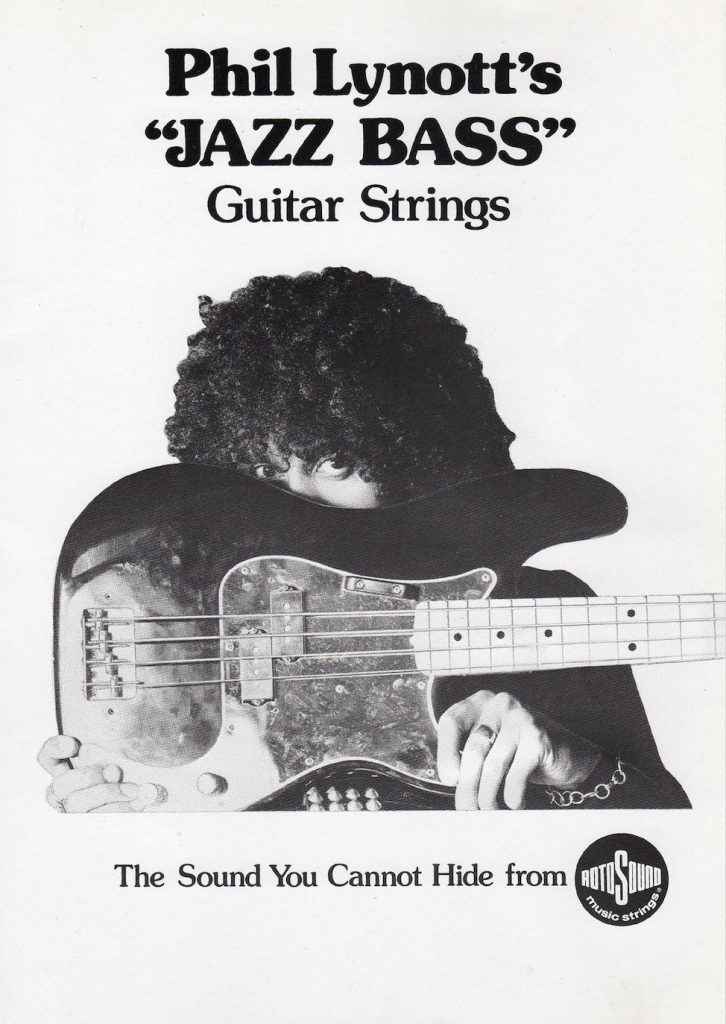

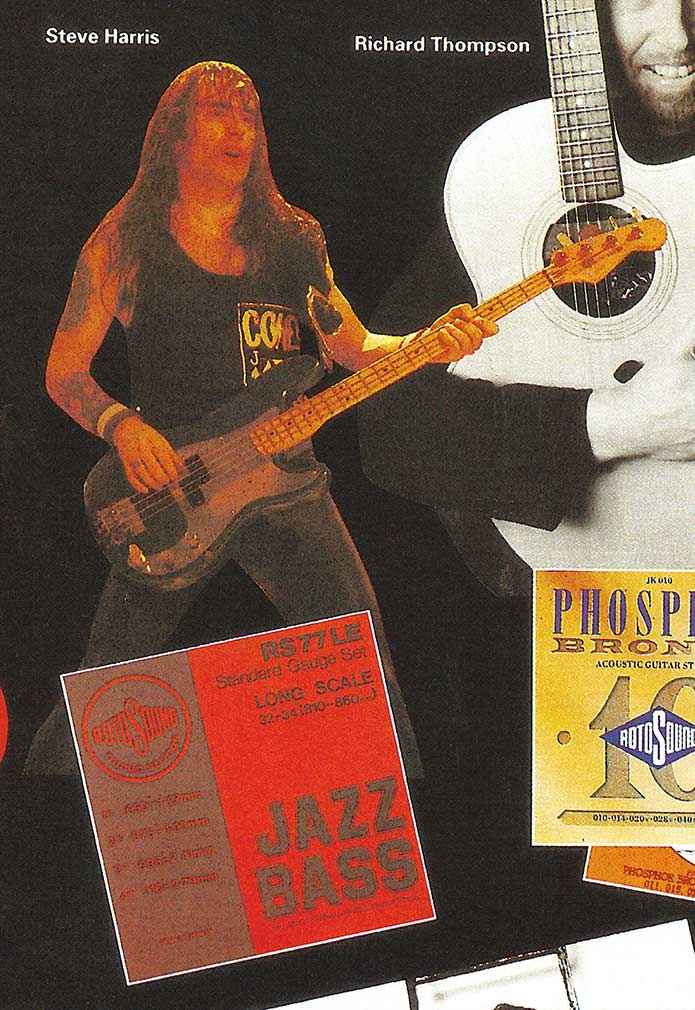

Jazz Bass 77

Monel Flatwound -

Tru Bass 88

Black Nylon Tapewound -

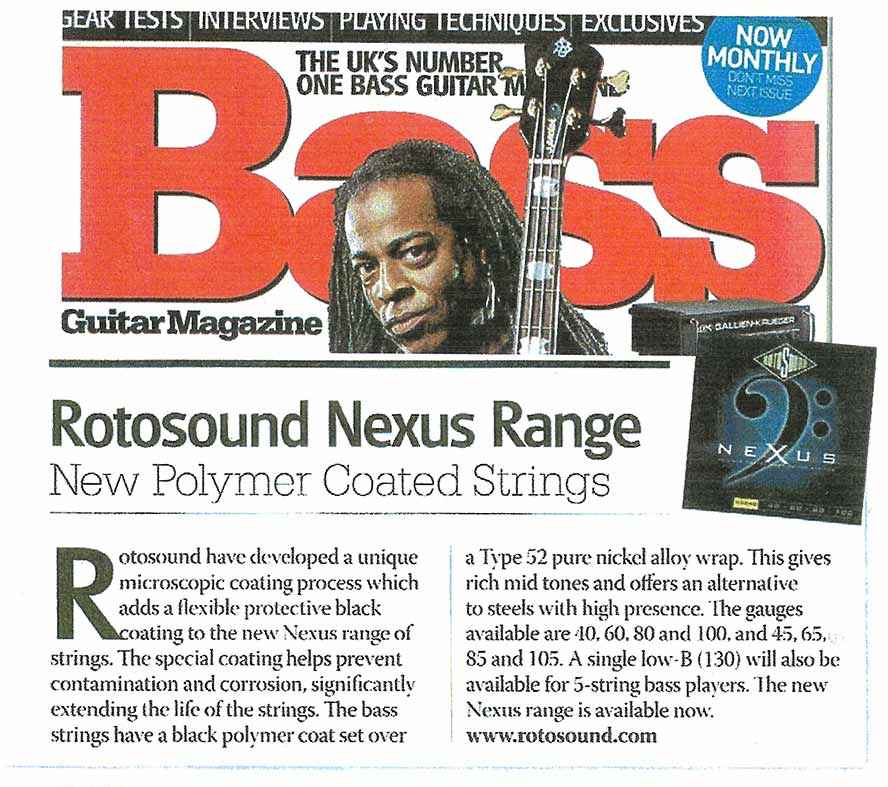

Nexus Bass

Coated For Extended Life -

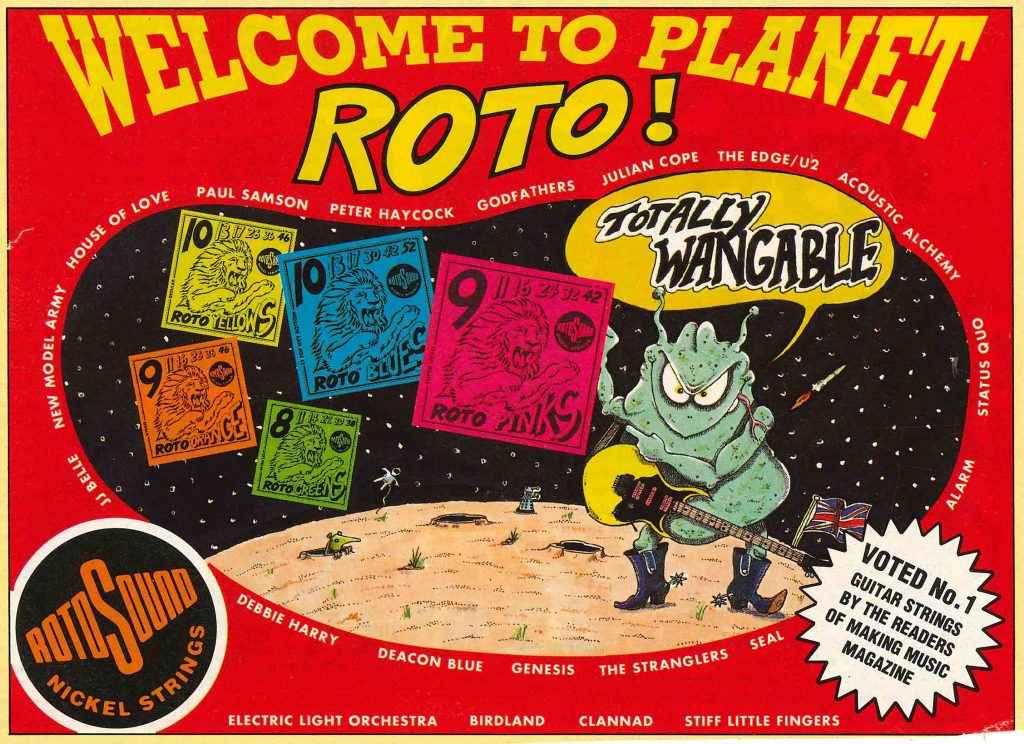

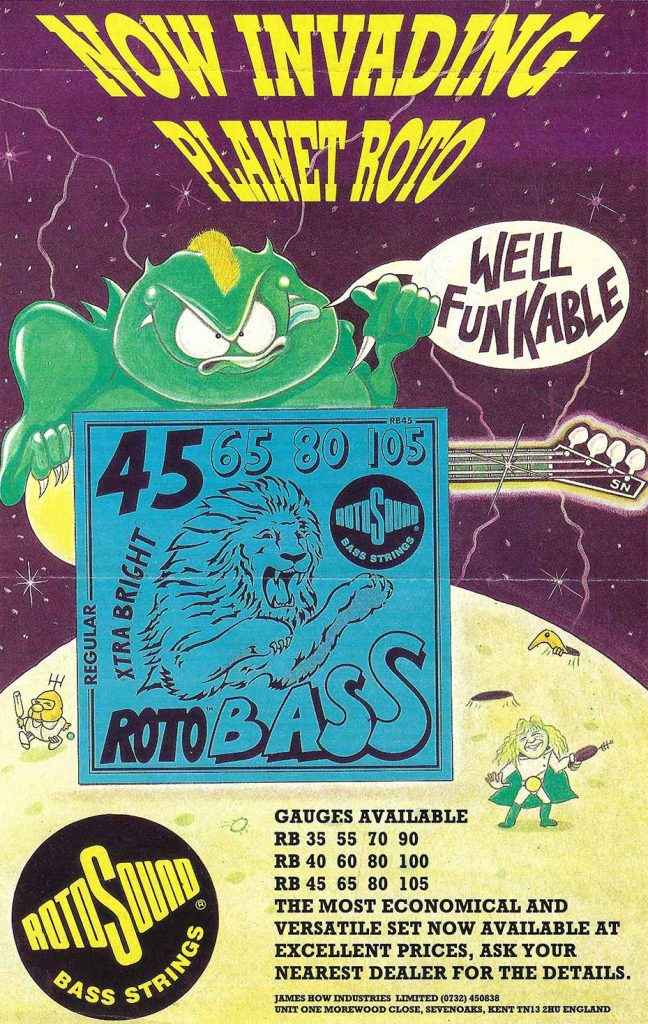

Roto Bass

Nickel Roundwound -

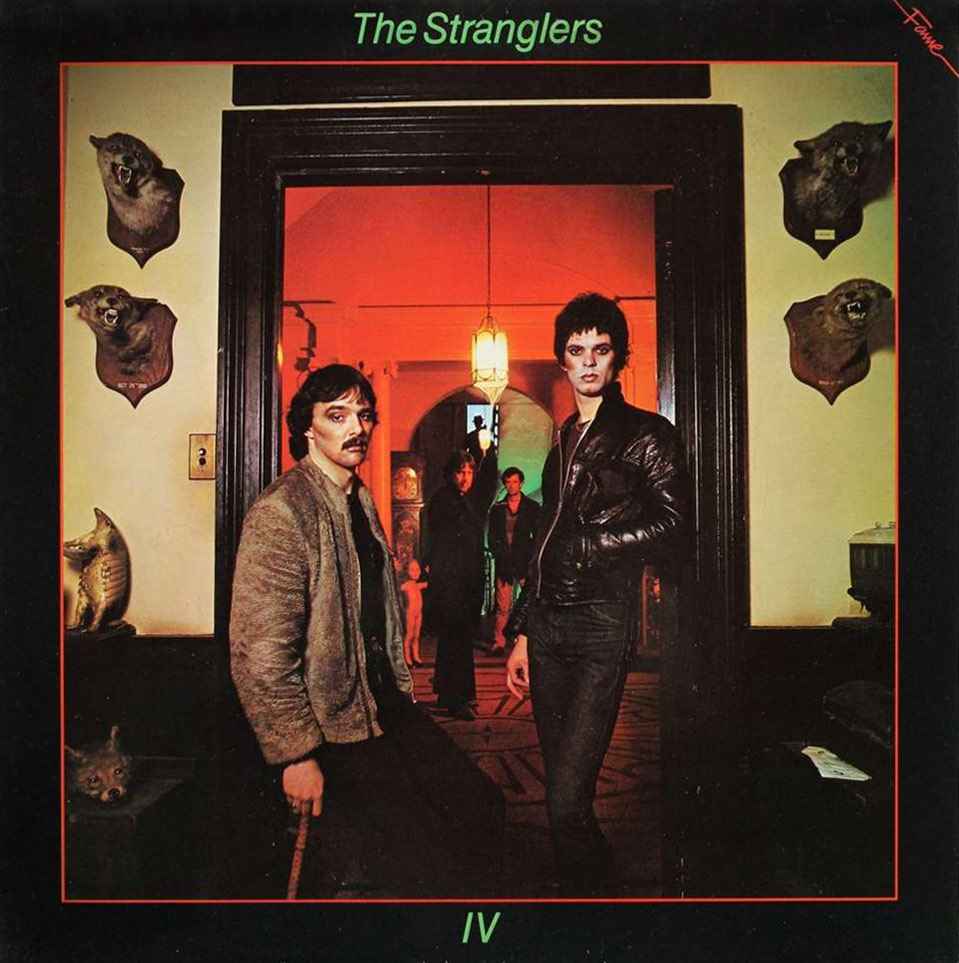

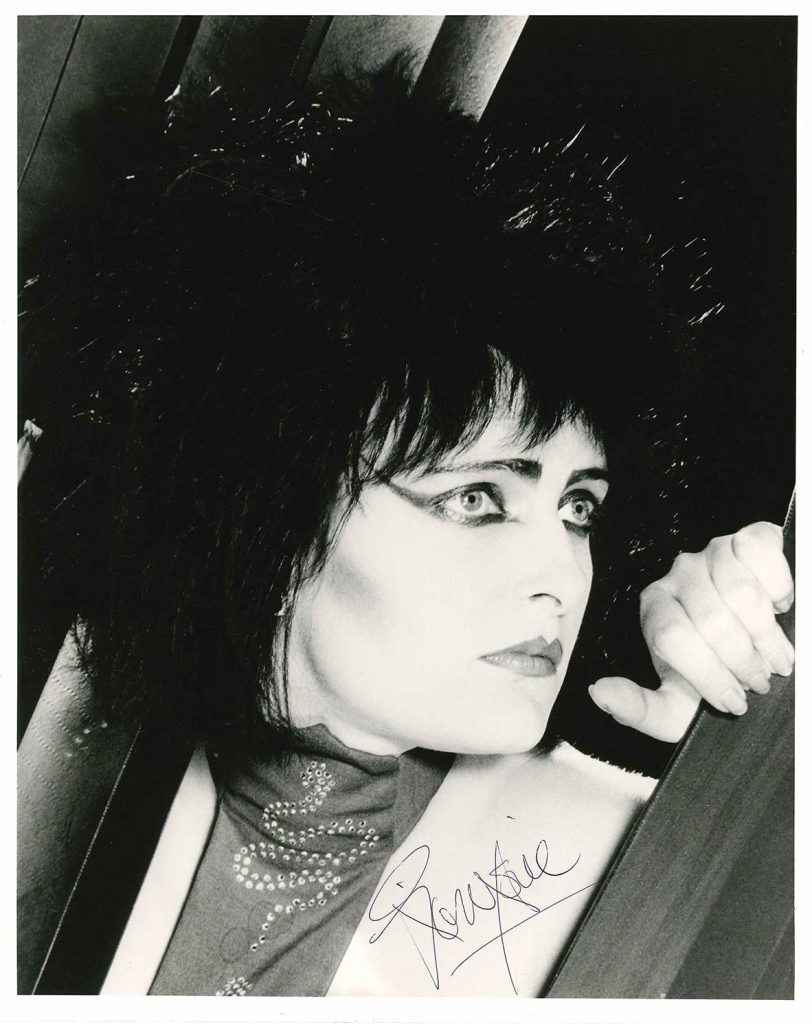

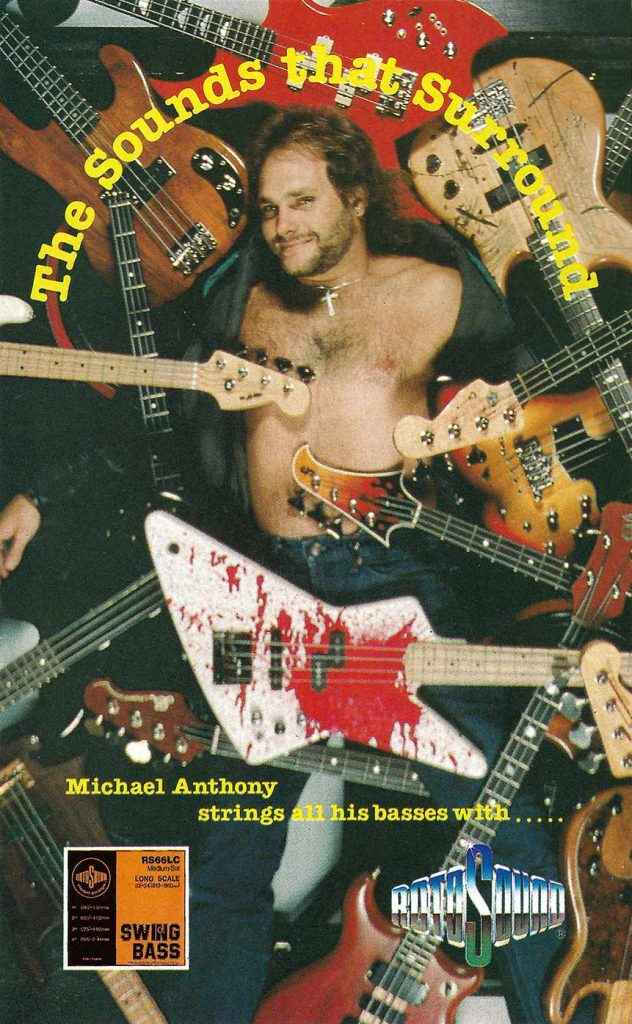

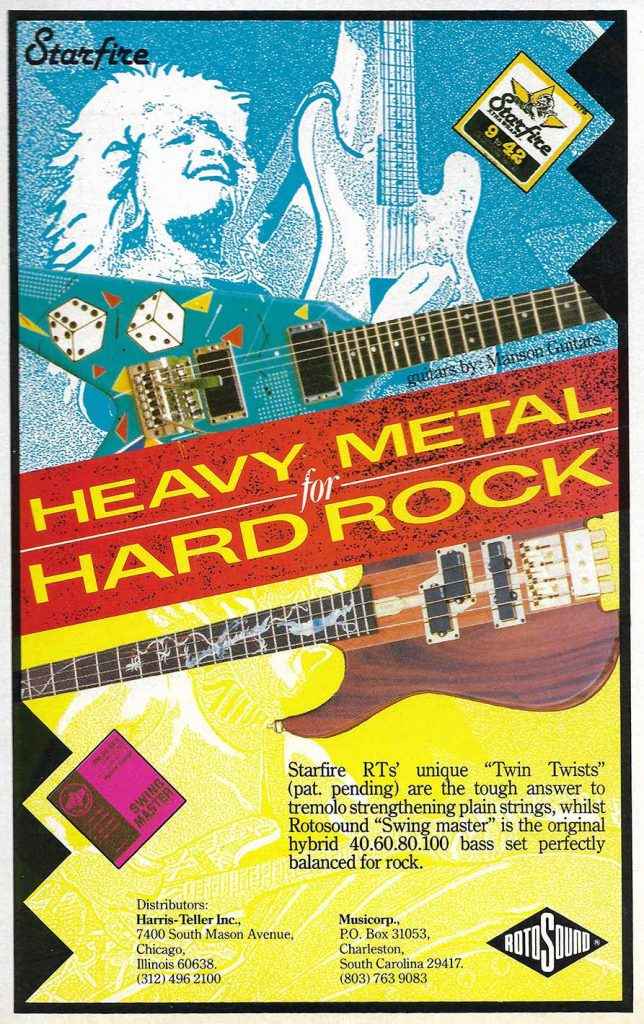

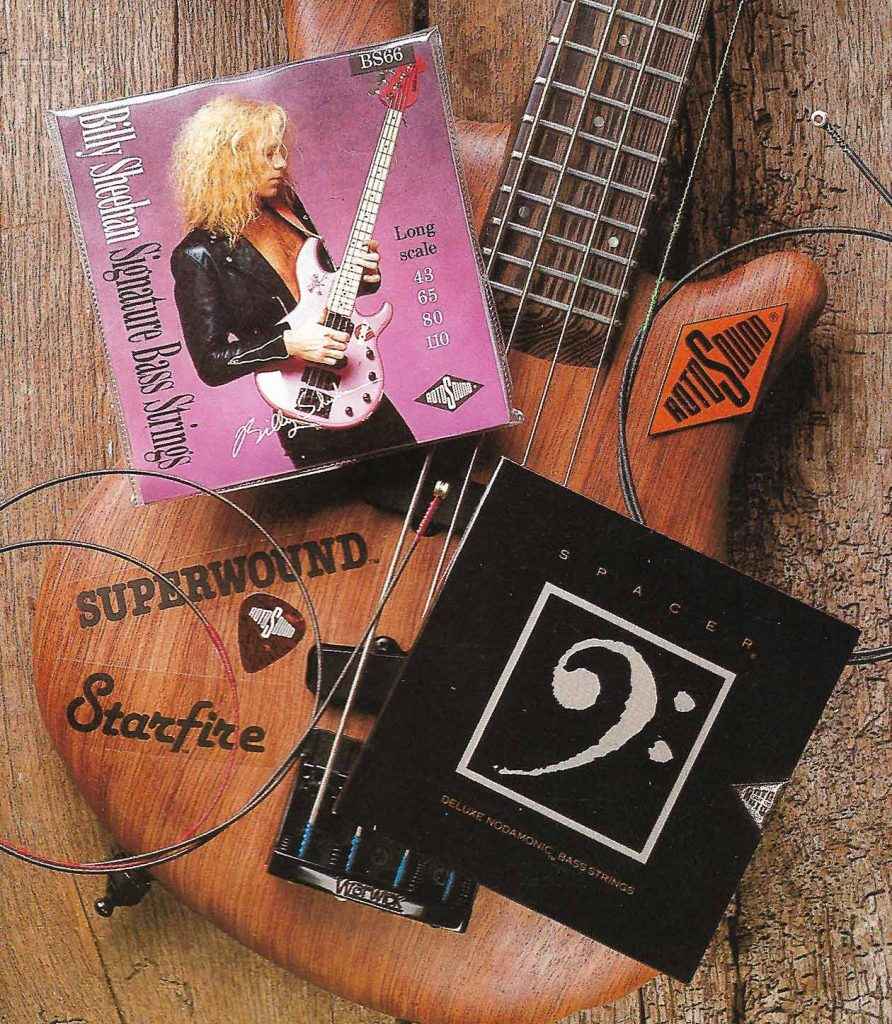

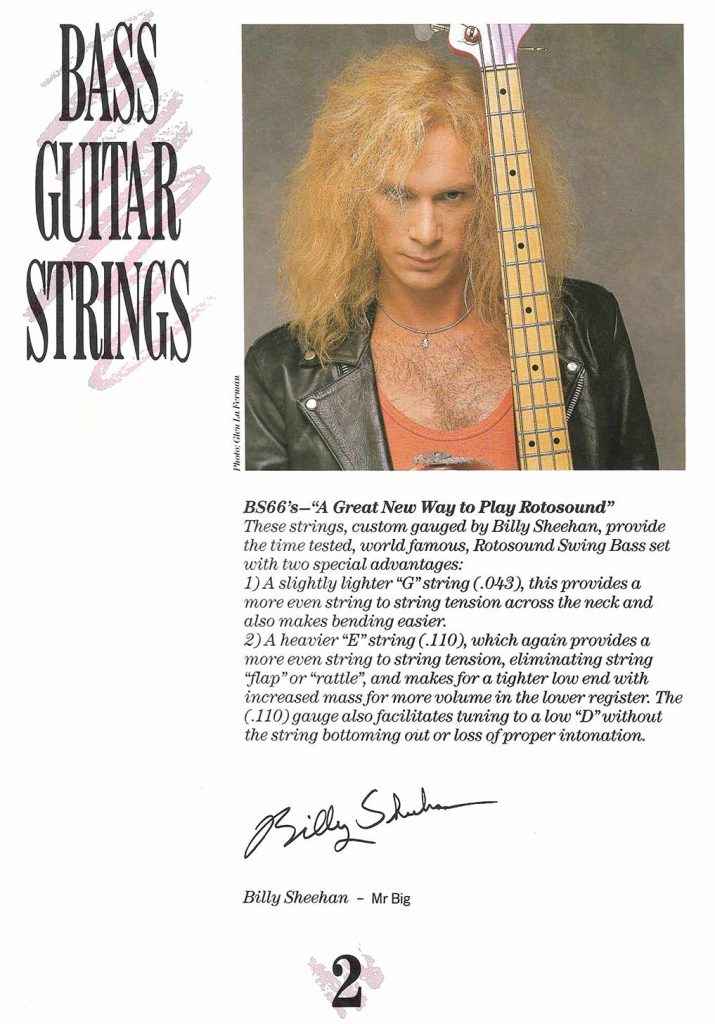

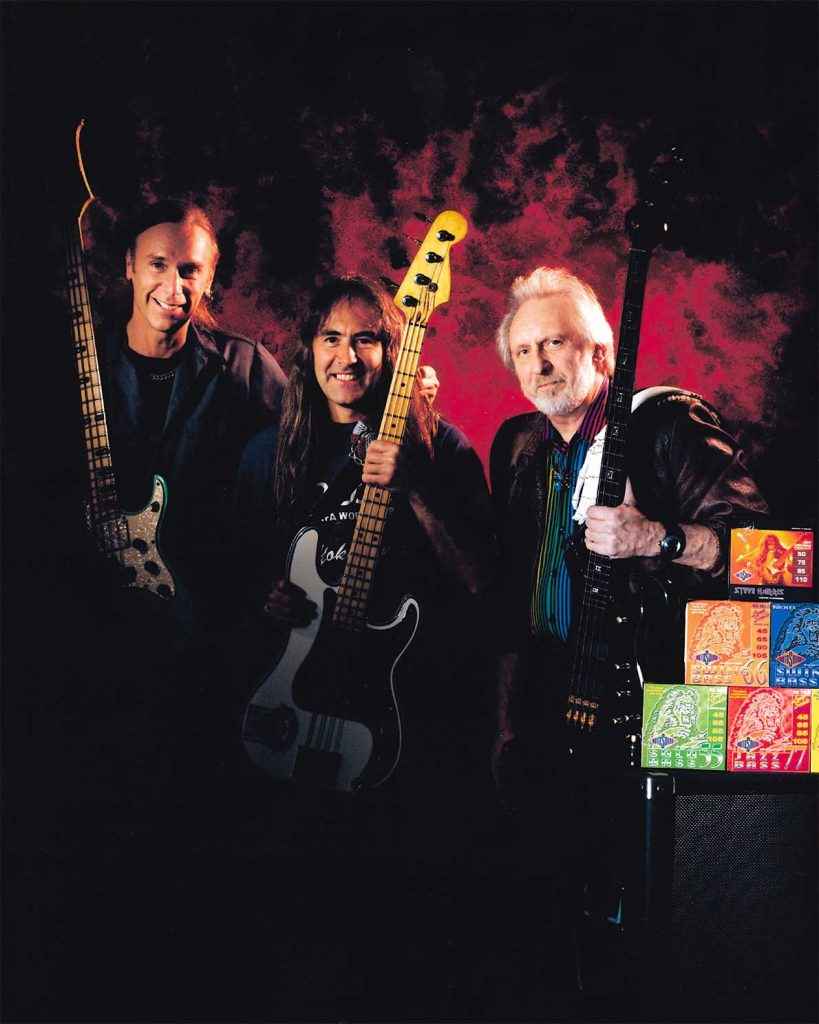

Signature Sets

Custom Gauges From Iconic Players

-

Ultramag Bass

- Accessories

- Merchandise

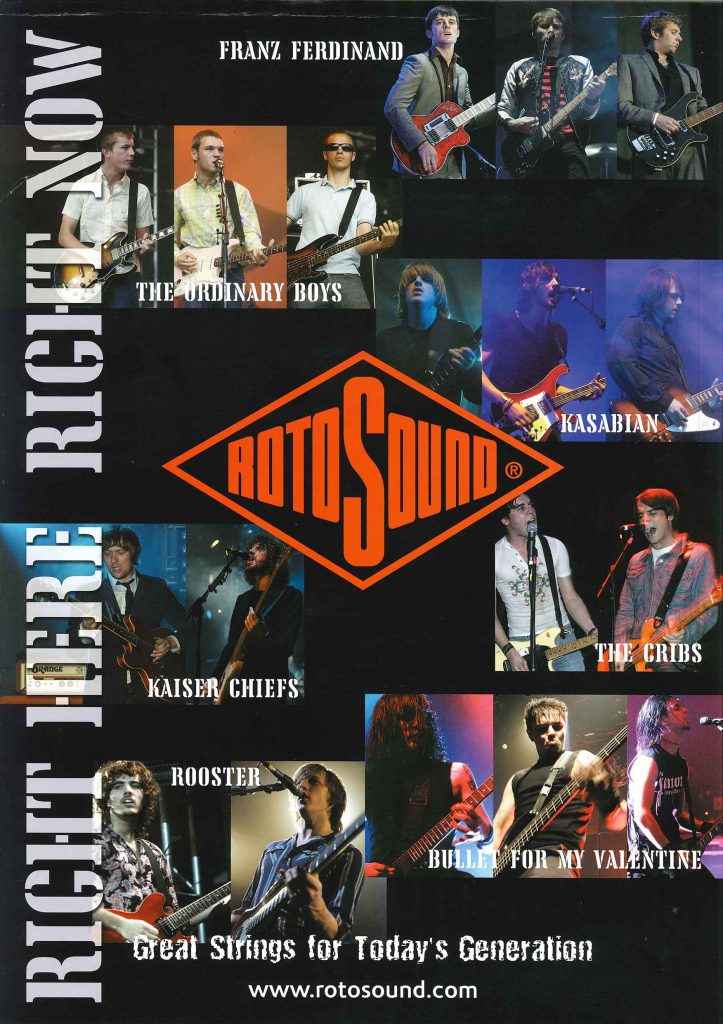

- Players

- Our Story

- Find Us

- Blog

Menu

- Strings

-

Ultramag Bass

Type 52 Alloy Roundwound -

Bronze Bass 44

Phosphor Bronze Acoustic -

Solo Bass 55

Stainless Steel Pressurewound -

Swing Bass 66

Stainless Steel Roundwound -

Dropzone 66

Designed For Drop Tuning -

Funkmaster 66

Made For Slap Bass -

Jazz Bass 77

Monel Flatwound -

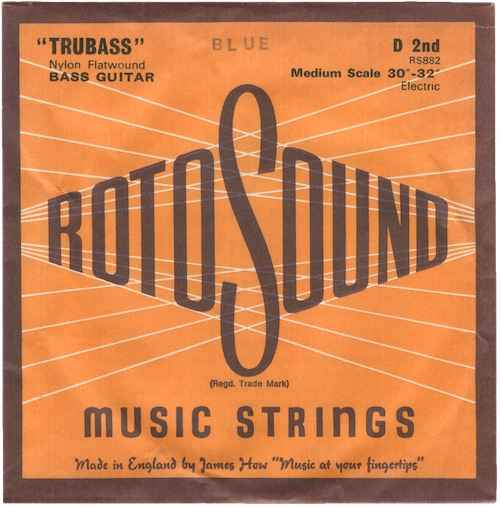

Tru Bass 88

Black Nylon Tapewound -

Nexus Bass

Coated For Extended Life -

Roto Bass

Nickel Roundwound -

Signature Sets

Custom Gauges From Iconic Players

-

Ultramag Bass

- Accessories

- Merchandise

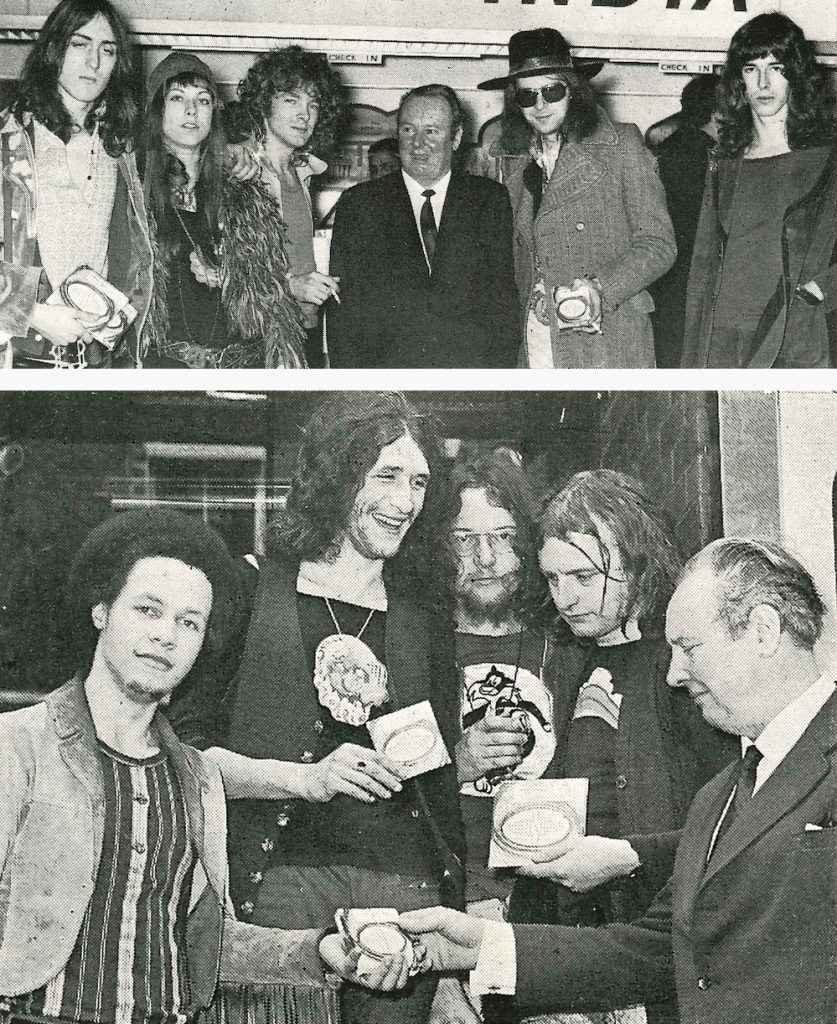

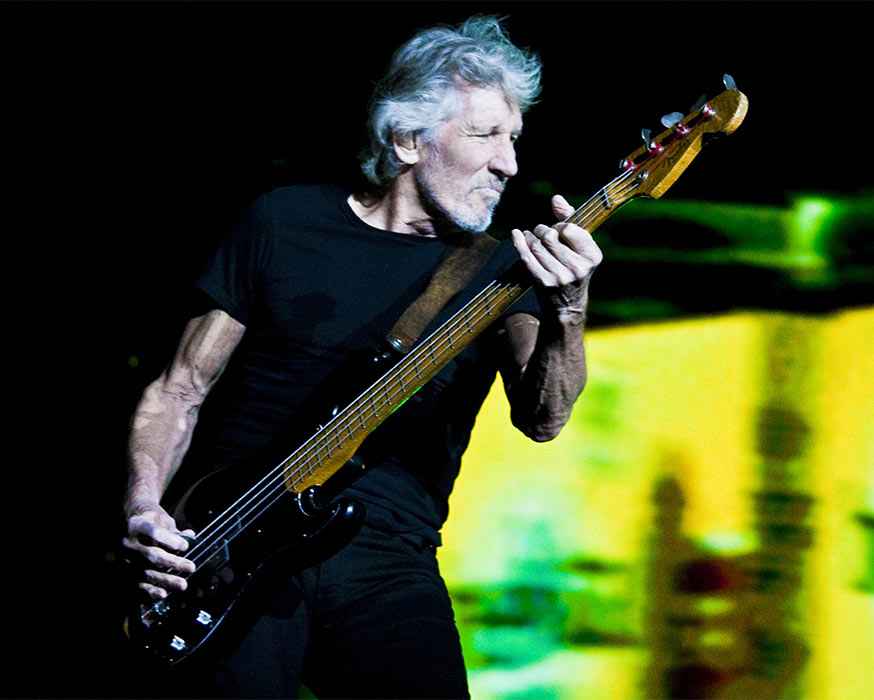

- Players

- Our Story

- Find Us

- Blog

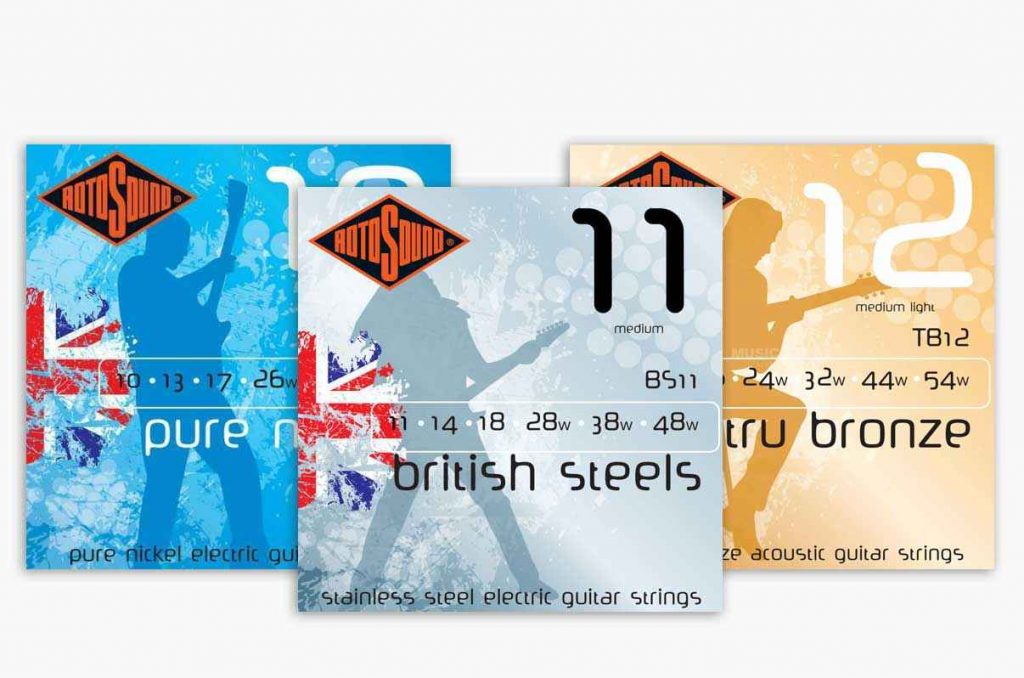

- Strings

-

Ultramag Bass

Type 52 Alloy Roundwound -

Bronze Bass 44

Phosphor Bronze Acoustic -

Solo Bass 55

Stainless Steel Pressurewound -

Swing Bass 66

Stainless Steel Roundwound -

Dropzone 66

Designed For Drop Tuning -

Funkmaster 66

Made For Slap Bass -

Jazz Bass 77

Monel Flatwound -

Tru Bass 88

Black Nylon Tapewound -

Nexus Bass

Coated For Extended Life -

Roto Bass

Nickel Roundwound -

Signature Sets

Custom Gauges From Iconic Players

-

Ultramag Bass

- Accessories

- Merchandise

- Players

- Our Story

- Find Us

- Blog

Search

Close this search box.